Welcome to Solvent Recovery

"Solvent Recycling Machine - Innovative Recycling"

High-Efficiency Recovery: Achieve up to 80 to 85% recovery rate.

Durable Construction: 304 stainless steel tank and air-cooled condenser.

Easy Maintenance: Vertical distillation vessel for hassle-free cleaning.

Safety Features: Explosion-proof electric panel, smoke detection system, Pressure safety switch, Auto cut operation, high Temperature Alarm System, Double jacket Oil bathed system, Indirect Heating system.

Automatic Operation: PLC controls and continuous filling system.

Versatile Applications: Multiple capacities (30L, 60L, 100L, 200L, 400L) and Customised for various industries.

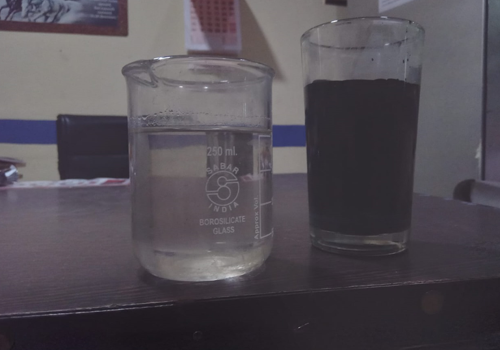

Live demonstration of Solvent Recovery Machine at our Unit.